MANUFACTURER / OEM SERVICES

We help you keep your customers happy

so you can focus on growing your business

For two decades Sagent has helped manufacturers lower their total cost of product ownership by delivering communications infrastructure support services that compliment new product development and device deployment.

We offer network equipment support that include a suite of new product introduction, retrofit and rework, and end of life solutions that our manufacturer partners offer their customers to drive new and creative contracts. Specific services may include things like expedited repair services, competitive displacement programs, and multi-vendor support contracts.

MANUFACTURER REPAIR SERVICES

US BASED RMA PROCESSING

Improved Customer Satisfaction

As a manufacturer your priority is often on your technology roadmap. Somewhere along the line, providing your own factory repairs almost became more trouble than it was worth. Rising costs, longer turnaround times, unhappy customers – we get it.

Your successful achievement of RMA service level agreement performance can make or break future sales opportunities and poor performance can risk the introduction of third party repair competition. When you work with Sagent, we will help you deliver US-based, manufacturer quality, equipment repair tailored to meet the contractual agreements you have in place with your customers. We repair more than 65,000 SKUs from over 100 manufacturers annually with a 97% yield and 98% on time delivery.

MANUFACTURER DATA ANALYTICS FOR REPAIR SERVICES

predict & avoid repairs

Turn Interesting Data into Actionable Data

Included with each of our manufacturer repair services program is a suite of data analytics and business intelligence dashboards, powered by our Sagent Insights platform, purpose built to provide you with root cause analysis and trending information on the returns you get from your customers.

Through a web-based portal we give you Insight into your product returns to help reduce reoccurrence. Our platform will present you with the data to identify avoidable repair events, hold your contract manufacturers accountable, and reduce repair volumes. We don’t just repair your equipment; we also find the problem that caused it and help you, help your customers, to prevent future events.

OEM REPORTING

TREND REPAIR DATA

TO IMPROVE RELIABILITY

Some reporting is “interesting”, but it can only be used to reduce your total cost of ownership if it is “actionable.” Sagent has developed dynamic reporting around our repair services to help our clients act to avoid failure events.

For each repair, we capture and report on the root cause of each failure and can pinpoint the means to avoid it in the future. Our customized software was developed specifically for network operators and tracks failure data at both macro and micro levels.

Our data monitors failure trends by geography, site location, technician responsibility, OEM platform and specific part numbers so that we can deliver actionable data to help prevent future incidents.

Sagent Insights: Avoidable Repairs Overview

MANUFACTURER PRODUCT LIFECYCLE SERVICES

RETROFIT & ENGINEERING

CHANGE NOTICE

Minimize Disruption To Your Manufacturing and Product Rollout Process

Occasionally components need to be swapped, and circuit boards need to be modified, after the initial product rollout. Don’t let these retrofit projects hurt your ability to meet customer demand and promised delivery dates by slowing down your manufacturing process.

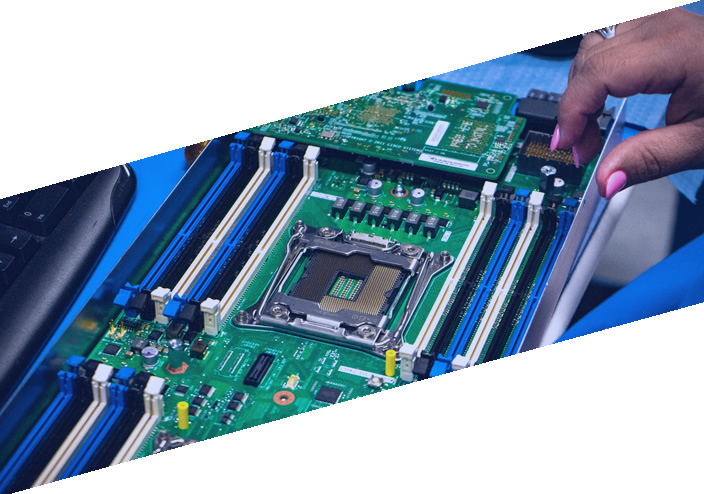

We deliver component retrofit and engineering change order services that allow manufacturers to maintain new product production. We employ more than 100 experienced technicians in our state-of-the art repair and technology center and can deliver manufacturing quality component replacement services that include a final system test to verify your products are ready for redeployment to your customers.

MANUFACTURER SALES ENABLEMENT SERVICES

Competitive Displacement

The Easiest Path to Beating the Competition

Wouldn’t it be easier if you could just ask your customers to take out their currently deployed products and install yours? Sounds simple enough, your customers know that your products perform better. Unfortunately, there are issues with book value, depreciation schedules and approvals from finance that make this much more complicated. So, what can be done?

Sagent offers our manufacturer partners competitive displacement programs where we provide a guaranteed buyback offer for the competitors’ products that you want to replace. This gives your customers the ability to upgrade to the best product (yours) and address the financial issues to get it approved.

MANUFACTURER SALES ENABLEMENT SERVICES

TRADE-IN PROGRAMS

Create New Budget Dollars For Your Customers

It’s difficult to sell to a customer that has no available capex. It’s also difficult to address this objection unless you are willing to offer deep discounts or terms that put your company at risk. But there is a good chance that your customer has a way to buy your products that they don’t yet realize.

Sagent has generated $46M in proceeds for our clients in the past 12 months. And these proceeds can be used to purchase your products. Sagent evaluates any surplus equipment your customers may have and, through our direct purchase and consignment programs, remarkets this equipment for resale. The resale proceeds create new budget dollars used to by your customers to buy your products.

MANUFACTURER SALES ENABLEMENT SERVICES

EOL/EOS SERVICES

End-Of-Life Products Don't Need To Be The End Of Your Revenue Stream

It’s no secret that your customers have begun shifting their spending priorities and have started to look for new ways to leverage their existing equipment…including products that are in EOL status.

With Sagent’s outsourced maintenance programs you can continue to offer your customers a solution to support EOL products, creating a happy customer and keeping your contracts with them in place.

Under a white-label service model, Sagent will provide your customers 24x7 remote technical support, deployment of advanced exchange devices from our 300 field stocking locations, and a “smart-hands” technician onsite in as little as 4 hours.

MANUFACTURER SALES ENABLEMENT SERVICES

RENEW PROGRAMS

Create New Budget Dollars For Your Customers

As a manufacturer there will be a point in your sales process where you are going to have a customer that needs to return your product. Maybe they purchased the wrong item, maybe they purchased too much, or maybe the return is a result of a stock rotation program you have in place with them. Regardless of the reason for the return, your company now has product that is not technical in “new” condition. We have found that many manufacturers don’t have a process for selling this category of product. How should you market this product for sale? Should you offer a warranty? What type of discount should be offer for a product in less than new condition? Sagent can help you answer these questions and maximize the value on these products.

For two decades Sagent has excelled in the refurbishment and resale of product that doesn’t quite fit in a new condition category. Leveraging our 130,000 sf/ft operations center in Coppell, TX and our team of more than 100 technicians and engineers we will help you inspect these products, test and refurbish them if necessary, and then marketing them to our global customer base of more than 1,700 customers. We will handle all of the marketing, the presales activity, and the post-sales support including warranty management. Our business intelligence systems also allows us to track and trend market demand for your product and monitor price points to ensure maximum value is realized.

MANUFACTURER COMPLEMENTARY SERVICES

- COMPONENT LEVEL TEST AND REPAIR

- COMPONENT REPLACEMENT AND ECN IMPLEMENTATION

- PRODUCTS SCREENING AND REFURBISHMENT

- ITAD SERVICE AND DATA WIPING

- MULTIVENDOR CONFIGURATION SOLUTIONS

- RACK & STACK AND SITE KITTING

- PREDEPLOY INTEGRATE & TESTING

- PRODUCT VERIFICATION

ACTIVE CERTIFICATIONS